“Concrete In Practice” is our series of one-page guides, written in an easy-to-understand way.

Each guide will answer the "What, Why, and Hows" of each process, from preparation to pouring. Click on the tabs below to learn more!

Concrete From Start to Finish

-

Before a job begins, especially a large one, a concrete pre-construction meeting should take place to define and assign responsibilities for all parties involved.

-

When ordering ready mix concrete, be prepared to provide all the basic information needed.

-

Most concrete eventually cracks. Joints act as a pre-planned place for those cracks to hide.

-

Finishing concrete involves producing the desired surface texture, smoothness, and durability.

-

Curing is the maintaining of adequate moisture content and temperature in concrete at early ages so that it can develop the strength that a mix is designed to achieve.

-

Vapor barriers are materials that will minimize the transmission of water vapor from the subgrade into a concrete slab.

-

Temperature is an important factor in properly curing since the rate of hydration corresponds with strength development.

-

Cold weather is when the average daily temperature falls below 40°F for more than three days in a row. Cold conditions warrant precautions when placing, finishing, and curing.

PREVENTING & TROUBLESHOOTING CONCRETE OBSTACLES

-

Dusting is the formation of loose powder resulting from the disintegration of the surface of hardened concrete.

-

Scaling is the flaking or peeling of a finished surface of hardened concrete.

-

Crazing is the development of a network of fine random cracks on the surface of concrete or mortar.

-

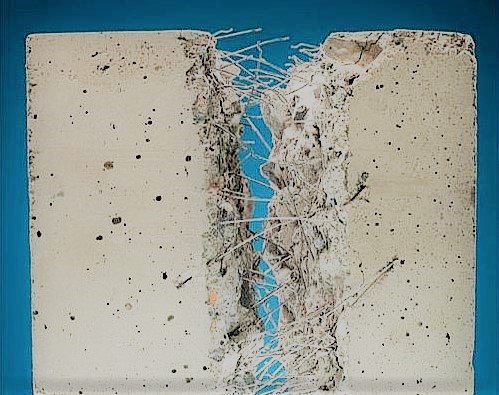

Concrete contracts and expands with changes in moisture and temperature, and deflects depending on load and support conditions.

-

Curling is the distortion into a curved shape by upward or downward bending of the edges.

-

Delamination concrete slab surfaces is the separated from the base from the top layer primarily due to premature and improper finishing

-

Blisters are hollow bumps on the concrete surface, typically from about a dime to 1 inch in size.

-

Different potential reasons for wall cracking.

-

Plastic shrinkage cracks appear on the surface of fresh concrete after placement and while concrete is still in its plastic.

-

Surface discoloration is the non-uniformity of color or hue on the surface of a single concrete placement.

-

Addition of water to ready mixed concrete after arrival to the location of the concrete placement.

Specialty Concrete

-

Grout as “a mixture of cementitious material and water, with or without aggregate, proportioned to produce a pour-able consistency without segregation of the constituents.”

-

High strength is a type of high-performance concrete generally with a specified compressive strength of 6,000 psi or greater.

-

Fiber-reinforced concrete is concrete that contains fibrous material to help with its structural integrity.

-

Self-consolidating concrete (SCC) is a highly flowable, non-segregating concrete that can spread into place, fill the form work and encapsulate the reinforcement without any means of consolidation.

-

Structural lightweight concrete has an in-place density (unit weight) on the order of 90 to 115 lb/ ft³ compared to normal weight concrete with a density in the range of 145 to 155 lb/ ft³.

-

Pervious concrete is a special type of concrete with a high porosity used for concrete flatwork applications. The high porosity allows for water to pass through it reducing runoff and recharging groundwater levels.

For projects of any size

Whether you’re a homeowner looking to build a new patio, or a contractor working on a new store or residence, we can help.